Vertiv Alber BDSU

Battery Monitoring Systems For UPS Battery Cabinets

Click here to jump to more pricing!

Overview:

- Banking, Financial and Insurance

- Data Center/Colocation/Hosting

- Government

- Healthcare

- Education

Designed in accordance with the institute of Electrical and Electronics Engineers (IEEE) recommendations for battery monitoring, the Alber BDSUi and BDSU-50 Battery Monitoring Systems are ideally suited for 12 and 16 volt sealed batteries. The monitoring system provides detailed battery information, optimizing useful battery life. Instead of waiting for the inevitable failure, you can continue to utilize your batteries longer and with confidence by knowing their true state of health.

The data center monitoring system provides detailed battery information, allowing for cost savings by optimizing useful battery life. Instead of waiting for an inevitable failure or replacing batteries prematurely to prevent problems, you can continue to utilize your batteries longer and with confidence by knowing their true internal condition.

Maximize Your Uptime with an Albér Battery Monitoring System

How Confident Are You That Your Batteries Will Be Available When You Need Them?

Unplanned data center outages present a difficult and costly challenge for organizations. While eliminating downtime altogether is a challenging undertaking, organizations can start with the most frequent cause of unplanned outages – uninterruptible power supply (UPS) battery failure.

In most cases, the ability to keep critical systems running through power outages is dependent on the UPS. However, a UPS is only as reliable as the batteries that support it. Batteries are one of the most “low-tech” components supporting today’s missioncritical data centers but they are the most vulnerable part of an UPS system. While the vast majority of unplanned outages last less than ten seconds, a single bad battery cell can cripple a data center’s entire backup system, particularly if adequate UPS redundancy has not been implemented.

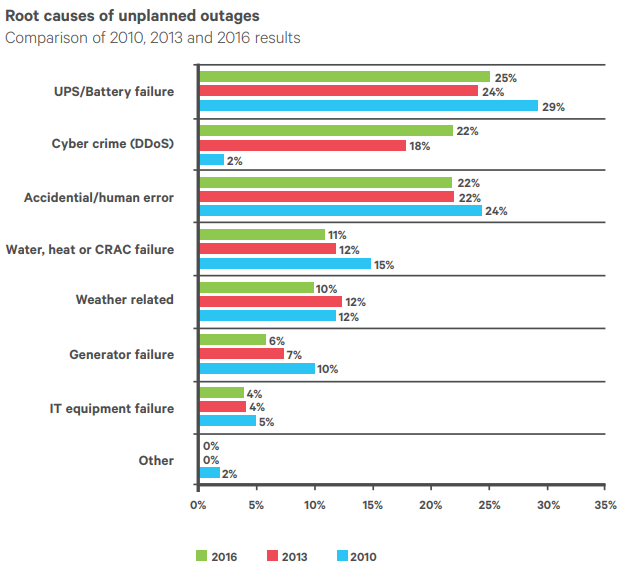

Ponemon Institute Study on Data Center Outages. Top root cause of unplanned outages experienced during the last 2 years

While batteries are one of the most “low-tech” components supporting today’s mission-critical data centers, they are the most vulnerable part of an UPS system.

Albér Battery Monitoring Systems Have Been Proven To Increase Critical Power Reliability

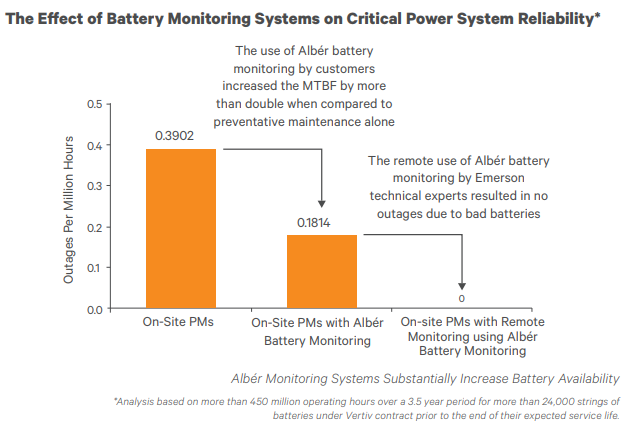

According to a recent analysis of actual field results of batteries in real-world UPS environments by Vertiv’s service organization, data centers with Albér battery monitoring systems installed on-site had a reduced rate of outages due to bad batteries.

The use of Albér battery monitoring systems by customers increased the Mean Time Between Failure (MTBF) by more than double when compared to preventive maintenance alone. While outages still occurred at some of these sites, most of these incidents were isolated to human error where customers were not watching the alarm data provided by the battery monitoring system.

The remote use of Albér battery monitoring systems by Vertiv technical experts resulted in no outages due to bad batteries. Not only does remote monitoring lift the burden of monitoring from internal personnel, but in many cases, it also integrates onsite and remote preventative maintenance activities in order to maximize battery availability.

Hardware

Designed in accordance with the Institute of Electrical and Electronics Engineers (IEEE) recommendations for battery monitoring, maintenance, and testing, the Albér BDSUi and Albér BDSU-50 Battery Monitoring Systems are ideally suited for 12 and 16 volt sealed battery applications. The Albér BDSU-50 is designed to be mounted on top of any brand of UPS battery cabinet or open rack while the Albér BDSUi is designed specifically to integrate into Liebert UPS battery cabinets.

An Albér Battery Monitoring System continuously scans and trends all critical battery parameters, providing detailed reports identifying probable root causes and recommended corrective actions. The result: a reliable, effective system that is efficient to deploy and intuitive to use.

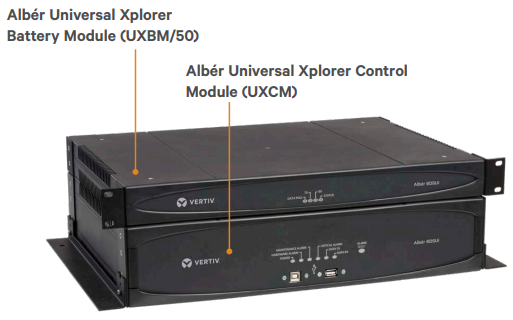

The systems consist of two primary components:

- Albér Universal Xplorer Control Module (UXCM) — a controller that stores the data, provides alarms, power and communication connections.

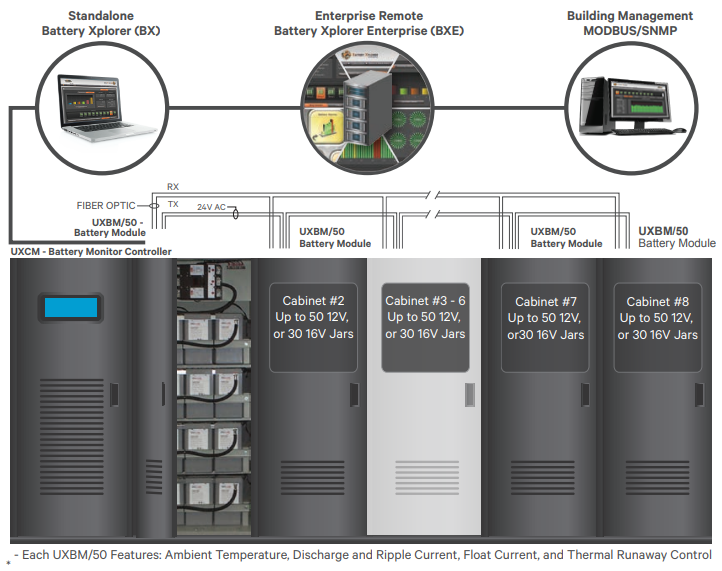

- Albér Universal Xplorer Battery Module (UXBM/50) —a battery module that measures all significant battery parameters and performs a patented DC resistance test (ohmic measurement process) to verify the integrity of the entire battery system. The first battery cabinet utilizes one Albér UXCM module and one Albér UXBM/50 module. Each additional battery cabinet uses only one Albér UXBM/50 module linked to the single Albér UXCM module on the first battery cabinet. An Albér UXCM can communicate with up to eight Albér UXBM/50 module or battery cabinets.

The Albér BDSUi is factory installed and tested inside Liebert UPS battery cabinets, eliminating the concerns associated with field installation. Since the Albér BDSUi is powered directly from the AC output bus of the UPS, it also eliminates the need to provide an external, protected AC power source. The Albér BDSUi is ideally suited for Liebert UPS external battery cabinets for 12V and 16V sealed battery applications:

The Albér BDSUi is factory installed and tested inside Liebert UPS battery cabinets, eliminating the concerns associated with field installation. Since the Albér BDSUi is powered directly from the AC output bus of the UPS, it also eliminates the need to provide an external, protected AC power source. The Albér BDSUi is ideally suited for Liebert UPS external battery cabinets for 12V and 16V sealed battery applications:

- Liebert NXL UPS

- Liebert eXL UPS

- Liebert NX 225-600 kVA UPS

- Liebert eXM UPS

Communication

Communication network connections are made by the Vertiv IS-UNITY-DP communication card, providing options for industry standard protocols. The card provides the ability to communicate with third-party Building Management Systems (BMS) and Network Management Systems (NMS). The web card protocol enables users to connect to the battery monitoring system via a web interface, premitting quick, real-time viewing of system status and alarms without the PC-based Battery Xplorer software.

Features:

SEE

Helps you proactively address battery related issues that you could never see before by allowing you to visualize all critical information and know the real state of health of your batteries at all times (in real-time or historical trending)

DECIDE

Helps you make more informed decisions, faster by analyzing data and utilizing built-in decision support functions that determine what matters and what doesn’t

ACT

Helps you take the right action with confidence at the right time by recommending the best corrective action

Flexibility

- Windows-based software or optional web-based software for real-time viewing, automatic data collection, data analysis, and report generation.

- Industry standard MODBUS protocol interfaces to third party building management systems via Ethernet.

- Optional TCP/IP interface for network or Internet communication via MODBUS or SNMP.

Higher Availability

- Scans pertinent battery parameters every 4 seconds, including total voltage, cell voltage, current and temperature.

- Automatic proactive internal DC resistance tests.

- Discharges are automatically detected and data saved for retrieval and playback.

- Trend analysis provides the ability to analyze performance and aid in trouble shooting.

- Maintenance by the Liebert Services local, factory-trained Customer Engineers promotes proper operation and longer service life for UPS and batteries.

Lowest Total Cost of Ownership

- Optimizes useful battery life -- Instead of waiting for an inevitable failure or replacing batteries prematurely to prevent problems, you can continue to utilize your batteries longer and with confidence by knowing their true internal condition.

- Provides the data for a battery replacement program, only replacing batteries that are identified as failing.

- Factory installed and tested to eliminate on-site installation and material logistics.

Increased Availability

- Detects open and shorted batteries

- Provides advance warning of an impending battery failure

- Eliminate the risk of human error

Reduced Maintenance Costs

- Enables extended maintenance intervals by basing maintenance on the condition of the batteries rather than arbitrarily timed schedules

- Automates all of the IEEE recommended practices for battery maintenance and testing except visual inspections

Reduced Replacement Costs

- Enables extended replacement intervals by basing replacement on the condition of the batteries rather than arbitrarily timed schedules

- Provides documentation to support warranty claims

Increased Safety

- Detects and mitigates catastrophic conditions including thermal runaway

- Minimizes shock, arch-flash, burn and chemical risks by reducing personnel exposure to batteries

- Meets the rigorous safety requirements for test and measurement equipment under UL 61010-1

Improved Compliance

- Allows users to comply with International Fire Code (IFC) 608.3 by providing the ability to detect and control thermal runaway

- Provides documentation to demonstrate compliance with regulatory standards

Management Software:

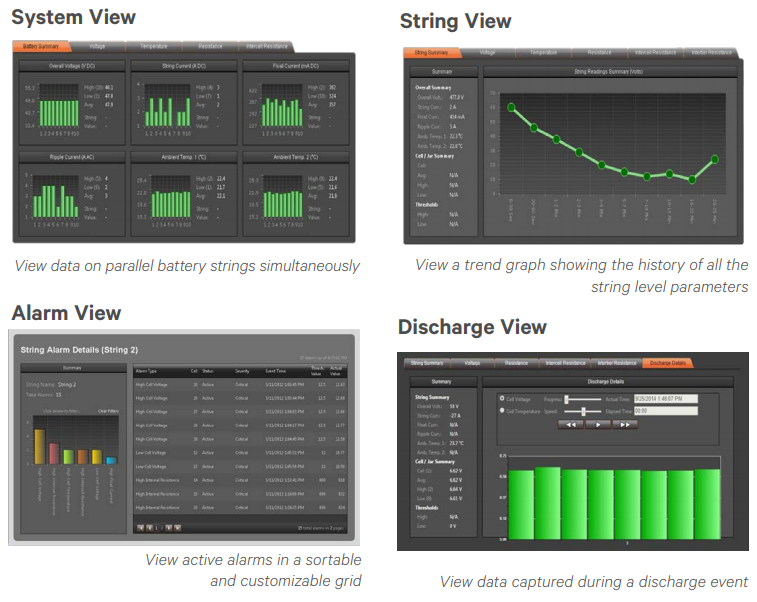

Albér systems’ user-friendly management software translates data into actionable insights to maximize the availability of critical power systems dependent on stationary back-up batteries. The simple, intuitive software allows users to set thresholds and alarm notifications, view graphs and trends, and generate reports. The reports have built-in decision support that analyzes the data and provides suggestions for the best course of action. Albér Battery Xplorer (standard) is ideally suited for single site users with a few strings of batteries while Albér Battery Xplorer Enterprise (optional) is ideal for multi-site users with many strings of batteries.

| Feature | Alber Battery Xplorer (Standard) |

Alber Battery Xplore Enterprise (Optional) |

Alber Battery Xplorer Enterprise Advantage over Alber Battery Xplorer |

|---|---|---|---|

| Platform | Windows OS | WEB | OS independent |

| Setup and Configuration | Not Applicable | ||

| Diagnostics and Service | Not Applicable | ||

| Real-Time Monitoring | Comparable level of functionality | ||

| Alarm & Event Management | Automatically centralizes alarms across multiple sites or systems and provides the ability to customize notifications | ||

| Report Generation | Comparable level of functionality | ||

| Data Management | Aggregates data from multiple sites or systems and stores it in a centralized database | ||

| Data Integration | Integrates data from other Albér stationary battery monitoring systems and Albér portable battery testing equipment | ||

| Multi-Site Navigation | Easily navigate across multiple sites and systems |

Specifications:

| Albér BDSUi and Albér BDSU-50 Specifications | |

|---|---|

| Main Chassis | |

| Module Level Measurements | Individual Module Resistance Individual Module Voltage |

| System Level Measurements |

|

| Power | 3.6 amps at 115 VAC ±10% 60Hz or 1.8 amps at 230 VAC ±10% 60Hz Configurations: 12-volt or 16-volt jars |

| Outputs | 24 VAC power: For up to eight UXBM/50 units Alarm contacts: Two Form C: Assignable as Maintenance or Critical, Programmable for latching or non-latching |

| Communication | Ethernet / Modbus TCP / BACnet IP / SNMPv1, v2c, v3 / Vertiv Protocol / HTTP / Email / SMS / Modbus RTU /BACnet MSTP |

| Software | Battery Xplorer / Battery Xplorer Enterprise (Optional) |

| Operating Environment |

|

| Parameters/Features | Number of cell channels: Up to eight strings of 40, 12 volt jars, six strings of 50, 12 volt jars or eight strings of 30, 16 volt jars |

| Monobloc Voltage | 12V range 0 to 18V 0.1% ±12mV y 16V range 0 to 24V 0.1% ±16mV |

| Internal Cell Resistance | 0 to 32,000μΩ, 5% of reading ±2μΩ |

| Dimensions and Weights: Albér Universal Xplorer Control Module (UXCM) |

|

| Albér Universal Xplorer Battery Module (UXBM/50) |

|

Documentation:

Download the Vertiv Albér BDSUi and Albér BDSU-50 Datasheet (.PDF)

Pricing Notes:

- Pricing and product availability subject to change without notice.